Enhanced bonding strength between stainless steel and plastic by using laser scanning array structure

-

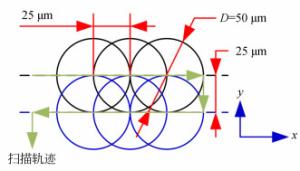

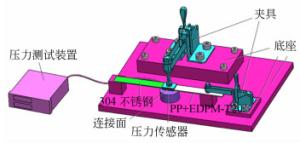

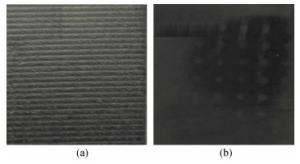

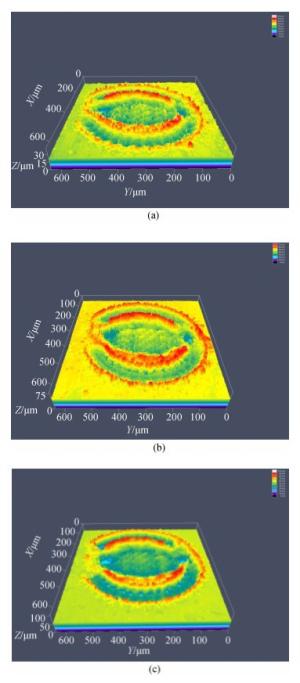

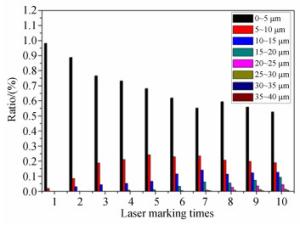

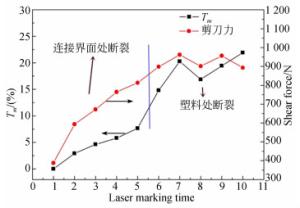

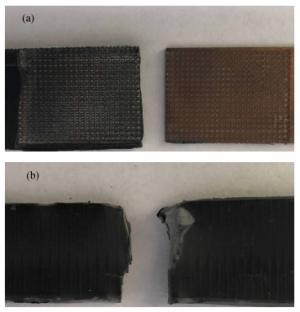

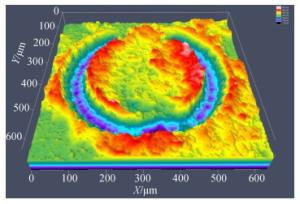

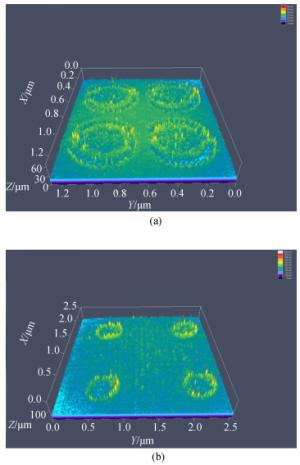

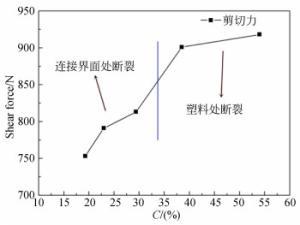

摘要: 本文采用光纤金宝搏188软件怎么用 器在不锈钢表面上制备圆形阵列结构来增强不锈钢与塑料的连接强度。研究了金宝搏188软件怎么用 制备的圆形阵列结构参数以及连接参数对不锈钢与塑料连接强度的影响。结果表明,不锈钢表面经过金宝搏188软件怎么用 扫描构形处理后能显著提高不锈钢与塑料的连接强度,在压力作用下,熔融塑料渗入金宝搏188软件怎么用 构造微孔形成的机械互锁是增强不锈钢与塑料连接强度的主要机制。金宝搏188软件怎么用 构形后不锈钢表面上的毛刺高度、数量以及覆盖率对连接接头的连接强度有重要影响。毛刺高度为10~20 μm,毛刺数量占比Tm小于14.82%时,不锈钢与塑料在连接面处断裂,剪切力随着Tm的增加而增加;当Tm值高于14.82%时,在塑料处断裂,且剪切力数值在塑料的平均拉伸断裂力(950 N)上下浮动。不锈钢与塑料连接接头断裂于塑料处时所对应的最小覆盖率为38.5%,此时剪切力为900 N。此外,金宝搏188软件怎么用 扫描处理过程中不锈钢与塑料连接的温度与压力对连接强度有重要影响,在加热温度为400℃时,不锈钢与塑料连接接头的剪切力最强;当压力为75 kN时,不锈钢与塑料连接接头的剪切力最强。

-

关键词:

- 金宝搏188软件怎么用 加工 /

- 金宝搏188软件怎么用 扫描构形 /

- 阵列结构 /

- 剪切力

Abstract: In this paper, the surface of stainless steel is treated with a fiber laser to prepare a circular array structure to enhance the bonding strength between stainless steel and plastic. The stainless steel is connected to the plastic under heat and pressure. In order to obtain the expected bonding strength of stainless steel and plastic, the effects of the circular array structure's parameters and bonding parameters on bonding strength are investigated. The results show that when the heating temperature is 400℃, the shear force of stainless steel and plastic bond is the strongest. When the pressure is 75 kN, the shear force of stainless steel and plastic bond is at its strongest. The height, quantity and coverage of burrs on the metal surface after laser treatment have an important effect on the bonding strength between stainless steel and plastics. When the proportion of burr number Tm value is less than 14.82%, the stainless steel and plastic fractured at the bond's surface and the shear force increases with the increase of Tm. When the Tm value is greater than 14.82%, the stainless steel and plastic fractured at the plastic, and the strength of the shear force fluctuates around the average tensile fracture force of 950 N. The coverage of the laser processing area has an impact on the connection strength, 38.5% is the minimum coverage of stainless steel and plastics when they fracture at the plastic, which then has shear force of 900 N.-

Key words:

- laser processing /

- scanning configuration /

- array structure /

- shear force

-

表 1 不锈钢和PP+EDPM-T20的物理性能和力学性能

Table 1. Physical and mechanical properties of stainless steel and PP+EDPM-T20

材料 密度/

(g·cm-3)熔点/

(℃)热降解温度/(℃) 抗拉强度/

MPa不锈钢 7.93 1 398~1 454 - ≥520 PP+EDPM-T20 1.05±0.02 160 450 ≥20 表 2 金宝搏188软件怎么用 器的参数

Table 2. Parameters of the laser equipment

参数 数值 参数 数值 波长/nm 1 064 平均功率/W 20 脉宽/μs 100 频率/KHz 25 脉冲能量/mJ 1 光斑/mm φ0.05 功率密度/mW·cm-2 510 范围/mm 100×100 表 3 不同温度下连接接头的拉伸强度

Table 3. Tension strength of joint at different temperatures

序号 温度/(℃) 断裂位置 剪切力/N 1 200 连接失败 0 2 300 连接界面 602 3 400 连接界面 705 4 500 连接界面 673 5 600 连接界面 639 -

[1] 益小苏, 张明, 安学锋, 等.先进航空树脂基复合材料研究与应用进展[J].工程塑料应用, 2009, 37(10):72-76. doi: 10.3969/j.issn.1001-3539.2009.10.019YI X S, ZHANG M, AN X F, et al.. Development and application of advanced aeronautical polymer matrix composites[J]. Engineering Plastics Application, 2009, 37(10):72-76. (in Chinese) doi: 10.3969/j.issn.1001-3539.2009.10.019 [2] KORSON C, STRATTON D. An integrated automotive roof module concept: plastic-metal hybrid and polyurethane composite technology[C]. Proceedings of the 5th SPE Annual Automotive Composites Conference, Bayer Material Science LLC, 2005: 14-15. [3] LEI D Q, WANG ZH F, LI J, et al.. Experimental study of glass to metal seals for parabolic trough receivers[J]. Renewable Energy, 2012, 48:85-91. doi: 10.1016/j.renene.2012.04.033 [4] ZHAO W P, BARSUN S, RAMANI K, et al.. Development of PMMA-precoating metal prostheses via injection molding:residual stresses[J]. Journal of Biomedical Materials Research, 2001, 58(4):456-462. doi: 10.1002/jbm.1041 [5] 徐飞, 田兴友, 王化.环氧SEBS胶黏剂的制备及性能研究[J].塑料科技, 2015, 43(5):56-60. http://d.old.wanfangdata.com.cn/Periodical/slkj201505008XU F, TIAN X Y, WANG H. Study on properties of SEBS epoxy adhesive and its preparation[J]. Plastics Science and Technology, 2015, 43(5):56-60. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/slkj201505008 [6] 丁文有, 何晓聪, 刘佳沐, 等.碳纤维增强聚合物-AA5052铝合金三层板自冲铆接性能[J].科学技术与工程, 2018, 18(25):143-147. doi: 10.3969/j.issn.1671-1815.2018.25.021DING W Y, HE X C, LIU J M, et al.. Performance of self-pierce riveting based on carbon fiber reinforced polymer-AA5052 aluminum alloy three-layer sheets[J]. Science Technology and Engineering, 2018, 18(25):143-147. (in Chinese) doi: 10.3969/j.issn.1671-1815.2018.25.021 [7] LI G, CHEN J H, YANISHEVSKY M, et al.. Static strength of a composite butt joint configuration with different attachments[J].Composite Structures, 2012, 94(5):1736-1744. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=54958defd04bc75fea17444a37d20784 [8] 袁辉, 刘鹏飞, 赵启林, 等.胶-螺混合连接承载力的参数影响研究[J].玻璃钢/复合材料, 2013(3):66-71. doi: 10.3969/j.issn.1003-0999.2013.03.015YUAN H, LIU P F, ZHAO Q L, et al.. Research on the influence factors of the bearing capacity for bonded-bolted hybrid joints[J]. Fiber Reinforced Plastics/Composites, 2013(3):66-71. (in Chinese) doi: 10.3969/j.issn.1003-0999.2013.03.015 [9] 马毓, 江克斌, 赵启林.制作工艺对复合材料胶-螺混合连接接头传力机理及承载力的影响分析[J].机械强度, 2011, 33(1):99-105. http://d.old.wanfangdata.com.cn/Periodical/jxqd201101020MA Y, JIANG K B, ZHAO Q L. Analysis of the impact of the fabrication technical process on the load transfer mechanism and carrying capacity of the bonded-bolted hybrid composite joints[J]. Journal of Mechanical Strength, 2011, 33(1):99-105. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jxqd201101020 [10] YEH R Y, HSU R Q. Application of porous oxide layer in plastic/metal direct adhesion by injection molding[J]. Journal of Adhesion Science and Technology, 2015, 29(15):1617-1627. doi: 10.1080/01694243.2015.1038955 [11] 贾振元, 赵凯, 刘巍, 等.工程塑料表面金属覆层的金宝搏188软件怎么用 定域精细去除[J].光学 精密工程, 2016, 24(1):94-101. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201601013JIA ZH Y, ZHAO K, LIU W, et al.. Localized and precision removal of metal coating on engineering plastics using NC laser milling[J]. Opt. Precision Eng., 2016, 24(1):94-101. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201601013 [12] HALDAR S, SAIN T, GHOSH S. A novel high symmetry interlocking micro-architecture design for polymer composites with improved mechanical properties[J]. International Journal of Solids and Structures, 2017, 124:161-175. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=39fcbc7dabbf25e978598e9b75a889c4 [13] MANDOLFINO C, LERTORA E, GAMBARO C. Effect of surface pretreatment on the performance of adhesive-bonded joints[J]. Key Engineering Materials, 2013, 554-557:996-1006. doi: 10.4028/www.scientific.net/KEM.554-557.996 [14] BAGHERI S, GUAGLIANO M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys[J]. Surface Engineering, 2019, 25(1):3-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d9ae146ed7ecfae346c34625830523a2 [15] ANNERFORS C O, PETERSSON S. Nano molding technology on cosmetic aluminum parts in mobile phones[R]. Sweden: School of Mechanical Engineering Lund University, 2007. [16] 张朝阳, 李中洋, 王耀民, 等.金宝搏188软件怎么用 冲击效应下的力学电化学微细刻蚀加工[J].光学 精密工程, 2012, 20(6):1310-1315. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201206022ZHANG CH Y, LI ZH Y, WANG Y M, et al.. Mechanical-electrochemical micro-etching under laser shock effect[J]. Opt. Precision Eng., 2012, 20(6):1310-1315. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201206022 [17] VILHENA L M, SEDLAEK M, PODGORNIK B, et al.. Surface texturing by pulsed Nd:YAG laser[J]. Tribology International, 2009, 42(10):1496-1504. doi: 10.1016/j.triboint.2009.06.003 [18] 程柏, 韩冰, 谷立山, 等.纳结构的连续金宝搏188软件怎么用 复合微纳探针刻划加工[J].光学 精密工程, 2015, 23(7):2043-2050. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201507030CHENG B, HAN B, GU L SH, et al.. Nanostructure machining by AFM probe combined with continuous laser[J]. Opt. Precision Eng., 2015, 23(7):2043-2050. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201507030 [19] ZHANG X M, YUE T M, MAN H C. Enhancement of ceramic-to-metal adhesive bonding by excimer laser surface treatment[J]. Materials Letters, 1997, 30(5-6):327-332. doi: 10.1016/S0167-577X(96)00229-7 [20] BABURAJ E G, STARIKOV D, EVANS J, et al.. Enhancement of adhesive joint strength by laser surface modification[J]. International Journal of Adhesion and Adhesives, 2007, 27(4):268-276. doi: 10.1016/j.ijadhadh.2006.05.004 [21] ROESNER A, SCHEIK S, OLOWINSKY A, et al.. Laser assisted joining of plastic metal hybrids[J]. Physics Procedia, 2011, 12:370-377. doi: 10.1016/j.phpro.2011.03.146 [22] XU F, LIU SH Y, FAN H Q, et al.. Enhancement of the adhesion strength at the metal-plastic interface via the structures formed by laser scanning[J]. Optics & Laser Technology, 2019, 111:635-643. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0b8049925a95b1a0cd8a357a781211b9 -

下载:

下载: